Mastering the Components of Oil Pump Structure for Optimal Performance

The oil pump is a vital component in an engine, responsible for lubricating and cooling various moving parts. Understanding the different components and their functions within the oil pump structure is essential for ensuring optimal performance and longevity of the engine. In this article, we will explore each component in detail, providing valuable insights into the intricate workings of an oil pump.

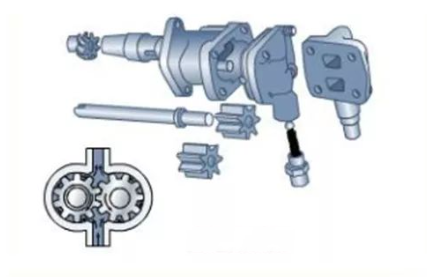

- Rotor and Shaft Assembly:

The rotor and shaft assembly is the heart of the oil pump. It consists of a centrally mounted shaft with lobes or gear teeth that engage with the pump housing. As the shaft rotates, it creates a vacuum effect, pulling oil from the oil pan or sump. The rotor and shaft assembly must be precisely manufactured and balanced to ensure smooth operation and minimal wear. - Pump Housing:

The pump housing encloses the rotor and shaft assembly, serving as a casing for the oil pump. It provides a sealed environment, allowing the pump to create the necessary pressure for oil circulation. The pump housing also contains various passages and grooves that direct the flow of oil, ensuring equal distribution to different engine components. - Pressure Relief Valve:

The pressure relief valve is a crucial component that prevents excessive oil pressure. It is designed to open when the oil pressure exceeds a certain threshold, allowing the excess oil to flow back into the oil pan. This mechanism protects the engine from potential damage caused by excessive pressure, ensuring optimal performance and longevity. - Oil Filter:

While not a direct part of the oil pump structure, the oil filter plays a significant role in maintaining the cleanliness of the engine oil. It is often located in close proximity to the oil pump and is responsible for removing contaminants such as dirt, metal particles, and sludge from the oil. Regularly replacing the oil filter is vital to prevent clogging and to ensure the longevity of the oil pump. - Drive Mechanism:

The drive mechanism connects the oil pump to the engine, facilitating its operation. It may consist of gears, belts, or chains, depending on the engine design. Proper maintenance of the drive mechanism is essential to maintain efficient oil pump operation.

Mastering the components of an oil pump structure is crucial for engine performance and longevity. The rotor and shaft assembly, pump housing, pressure relief valve, oil filter, and drive mechanism all work together to ensure the proper circulation, filtration, and pressure regulation of engine oil. By understanding the functionality of each component, engine technicians and enthusiasts can optimize oil pump performance, leading to improved engine health and reliability.

Implementing regular maintenance, such as oil and filter changes, along with inspecting and replacing worn components, will further enhance the functionality and longevity of the oil pump. Keeping these factors in mind will ensure a well-lubricated engine, reduced wear and tear, and enhanced overall engine performance.